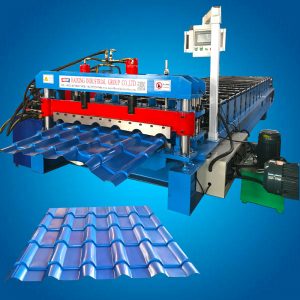

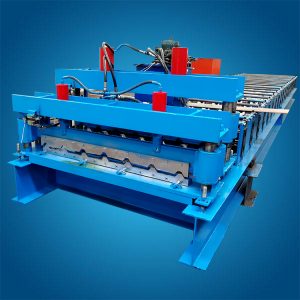

metal roofing forming machine

Brand: HX-1000 glazed

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit

- Description

- Inquiry

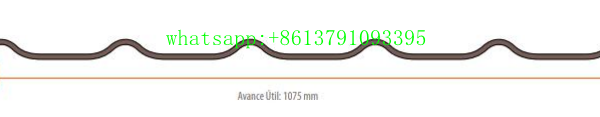

metal roofing forming machine parameter

metal roofing forming machine Raw material | |

| Raw material type | PPGL PPGI GI Gl coil |

| Width | 1220mm |

| Thickness | 03-0.8mm |

Roll forming part

metal roofing forming machine Roll fomring part | |

| Roller rows quantity | 11 rows |

| Diameter of shaft | φ70mm(Solid shaft) |

| Roller material | High grade 45# steel ( heat treatment , plated chrome on surface) |

| Shaft material | High grade 45# steel |

| Frame | 350 H Steel |

| Side panel thickness | 16mm |

| Cutting Type | Hydraulic Cutting |

| Blade of Cutting | Cr12 mov , quenching treatment |

| Cutting Tolerance | ± 1mm |

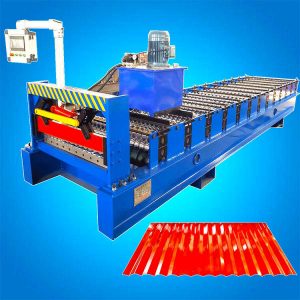

metal roofing forming machine Work Flow:

The machine work from feeding table, roll forming part,cutting head, then you will get the roof tile sheet. We use the Delta PLC, ohm wheel counter the products length, it can work automatically.

PLC operate table

This PLC conbinet is separated from machine,it has touch screen, and it connect wire lines by aviation plug. It is easy to connect and we number it, the cusomer connect them according to the corresponding numbers. It has manual and automatic, two work types. There are the wheels beneath the machine, so PLC conbine can move easily.

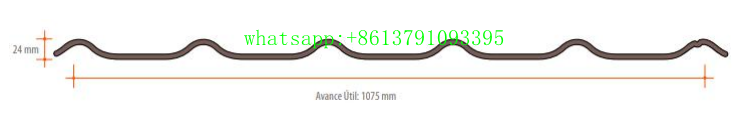

metal roofing forming machine products

(Click the picture, you can see the machine work video)

If you would like to know more details or have any questions, leave message to us. We will give you the quick reply. Glad we can communicate with you and make the close friends with you.

Our advantage:

1.we are professional in the field of the roll forming machine, we have the many different profile of the machine, our customers are from each countries in the world, if you would like to know the popular profile in your market, you also can inquiry to us. We can give you professional suggestion.

2.The manufacturing technology and product concept of the machine are constantly progressing and improving. The technical level of the products is continuously improved, the wheels are made more refined, and the raw materials of the paint are now using environmentally friendly materials, which conform to the ecological concept.

3.The motors and accessories of the products are all famous brands. Ensure the long-term use of the machine.

RFQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.