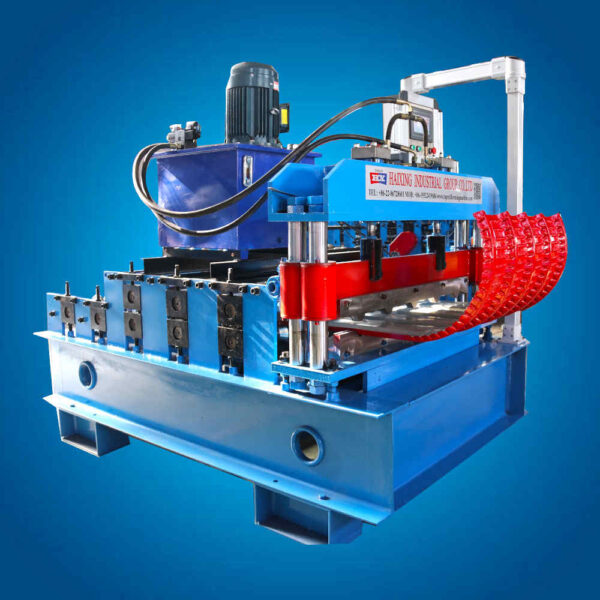

metal curving machine

Brand: HX-740

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.

- Description

- Inquiry

Metal curving machine parameter

| Raw material | PPGI,PPGL,GI,GL, |

| Raw material width | According to the profile of the machine, we can free to design the profile for the customer |

| Frame | 350H steel/400H steel/ Or customized |

| Side panel | 16mm/18mm/20mm according to the machine quality |

| Roller | upper: 3 rows lower: 4rows |

| Roller material | #45 steel, forged and chrom-plated |

| Motor | Delta/Siemens/ Or customized |

| Motor power | 4Kw/5.5Kw/ Or customized |

| Drive way | By chain |

| Chain size | 1 inch/ 1.5inch / customized |

| Cutting way | Hydraulic cutting |

| Cutting blade material | Cr12 mov |

| Hydraulic power | 5.5Kw/7.5Kw/ Or customized |

| Control system | PLC control system,(the operae table can rotate 360°) |

| PLC brand | Delta/Siemens/ Or customized |

| PLC language | Chinese/English/Spanish/Russian |

Metal curving machine work Flow:

1.Metal sheet → 2.Roll forming →3. Curving →4. Prodcuts

The meta sheet pass the roll forming part, it can correct the product level to ensure accurate access to the arching part, so it can ensure the product precise.

(Click curving sheet picture, you will watch the machine work video)

If you would like to know more details or have any questions, leave message to us. We will give you the quick reply. Glad we can communicate with you and make the close friends with you.

Our advantage:

1.we are professional in the field of the roll forming machine, we have the many different profile of the machine, our customers are from different countries in the world, if you would like to know the popular profile in your market, you also can inquiry to us. We can give you professional suggestion.

2.The manufacturing technology and product concept of the machine are constantly progressing and improving. The technical level of the products is continuously improved, the wheels are made more refined, and the raw materials of the paint are now using environmentally friendly materials, which conform to the ecological concept.

3.The motors and accessories of the products are all famous brands. Ensure the long-term use of the machine.

Related Products

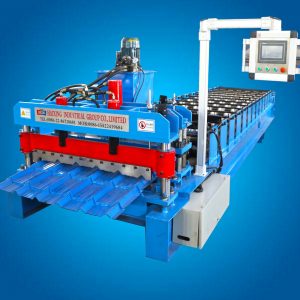

glazed tile roll forming machine

Brand: HX-1095 glazed

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit

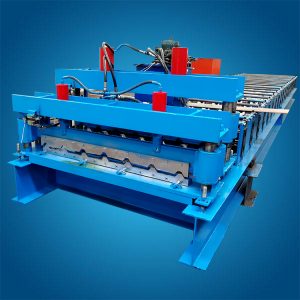

C8 trapezoidal forming machine

Brand: HX-C8 single layer machine

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.

Trapezoidal Iron Roofing Roll Forming Machine

Brand: HX-850

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit

roofing sheet machine

Brand: HX-1450 glazed

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.

R72 roof panel machine

Brand: HX-R72-101

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.

TR4 Double layer roof roll forming machine

Brand: HX-TR4+1035

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit

R panel sheet machine

Brand: HX-914 double layer machine

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.

roof tile making machine

Brand: HX-1064

FOB Price: Get Latest Price from inquiry

Min.Order Quantity: 1 set

Supply Ability: 200 sets per Month

Port: TIANJIN

Payment Terms: L/C,D/A,D/P,T/T,Western Union,Money Gram payments for offline orders.

Product Time: 25-45 working days after received the deposit.